1、派瑞林在磁性材料领域的应用

·钕铁硼:

耐酸碱和有机溶剂的腐蚀,耐盐雾(全涂敷的磁材浸7%的盐酸15天以上不腐蚀)。

固定表面碎屑,增加磁体强度,防止颗粒污染。

完全填充微孔、缝隙,无针孔及“砂眼”等涂装缺陷。

·软磁铁氧体:

超薄的绝缘层,能耐高压(镀22μm,可耐2400V的高压)。

微米级厚度均匀可控,大大节省磁环绕线空间,且不影响磁性。

良好的润滑效果,低磨损。

·钐钴等其他磁材:

完全同型,对复杂形状适应性好。

良好的耐盐雾效果。

增强磁体强度,降低较薄较脆弱的产品碎和断裂的机率。

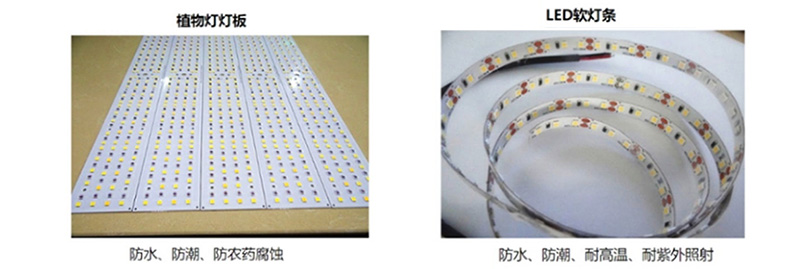

2、派瑞林在LED/OLED产品领域的应用

派瑞林涂层与传统的灌胶方式相比超薄轻质,不会显著增加LED重量,能减少支撑大型标牌所需的结构框架数量。其优良的阻隔性能和耐高温性能,可保护LED长期暴露于大气条件下和高温下免受腐蚀性液体、流体、气体和化学品侵蚀。派瑞林涂层出色的紫外线稳定性和光学清晰度,能够使LED抵御长时间的紫外线辐射,且不会影响LED的颜色或流明输出。派瑞林涂层具有低介电常数和低介电损耗,能避免LED电子信号传输出现吸收或损耗。因此近年来派瑞林涂层广泛应用于LED产品的防护上。

派瑞林涂层在LED/OLED产品上的应用场景:

·视频显示屏 ·记分牌

·电子公告板 ·船用照明

·交通标志牌 ·商用制冷车辆照明

·航空照明 ·户外照明

·交通信号灯

3、派瑞林(Parylene)在硅胶/橡胶制品领域的应用

硅胶是一种高活性吸附材料,在制造成各种硅胶产品时,硅胶产品表面形成静电效应,容易相互吸附,工人在操作的过程中不易分开,给操作带来了不便;同时,硅胶制品表面容易吸附灰尘和细菌。派瑞林工艺通过特有的CVD方式,在硅胶制品表面形成一层薄而透明的派瑞林膜层,因其具有优越的干润滑性、低摩擦系数和抗菌能力,改善了干涩、易吸附的表面状况,给使用者带来了极大的便捷。并且派瑞林纳米涂层可以渗入到硅胶制品表面的微孔结构中,与硅胶表面产生非常强的结合力,即便在有摩擦的环境中使用,也能保持派瑞林膜层的完整性。

·密封件 ·管道

·垫圈和O形圈 ·键盘

·罩壳 ·胶塞和柱塞头

·导管

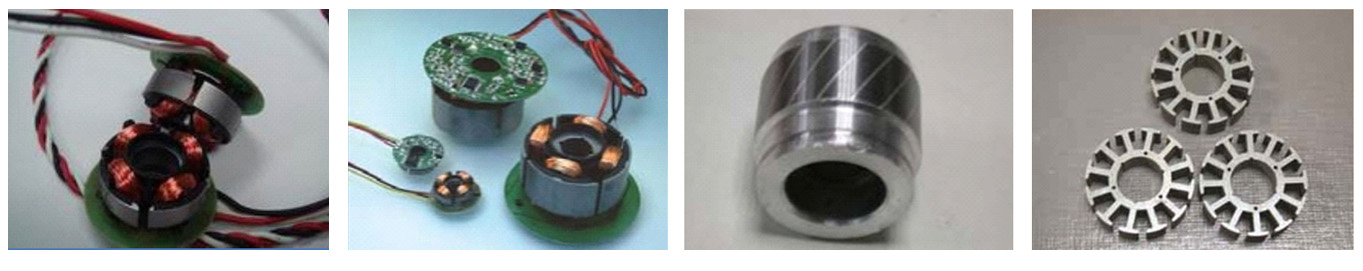

4、派瑞林在马达、风扇、线圈、铁芯等领域的应用

通常在潮湿或恶劣的环境下,因铁芯、转子、定子和马达的材料大多是用硅钢制成的,而硅钢本身很容易腐蚀生锈。所以这些部件在应用之前就要考虑防水、防腐蚀的解决方案。

派瑞林纳米涂层采用了一种独特的化学气相沉积工艺(CVD),其涂层致密无孔可以使铁芯、转子、定子、马达等一系列产品达到极佳的防潮、防尘、防腐蚀、耐高压的防护效果,特别是防尘防水等级能够达到IP68,是新一代铁芯、转子、定子马达等产品“三防”的首选方案,它能显著延长这些产品的使用寿命。